- Dongguan NHF Machinery Co., Ltd.

- francesgu1225@hotmail.com

- +8618689452274

✧ Advanced Technology

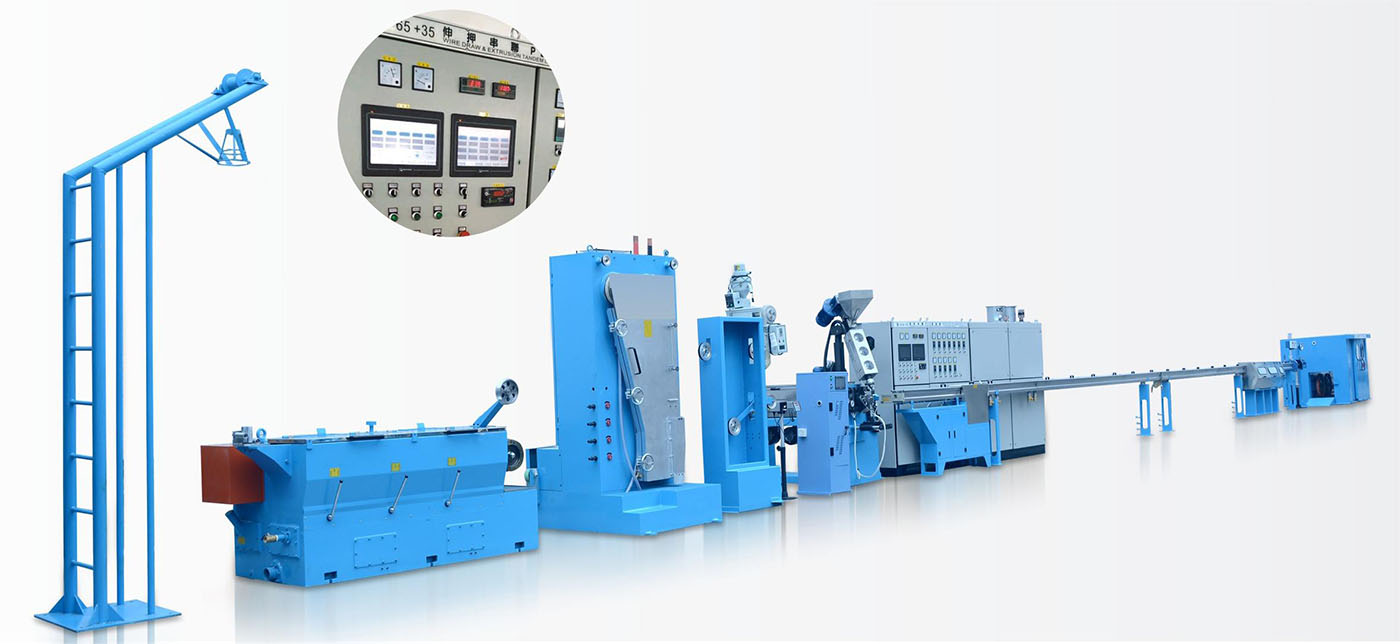

Tandem Line Extrusion Line: The Ultimate Solution for Advanced, High-Performance, Multifunctional, and Reliable Extrusion

As a leading manufacturer of extrusion equipment, we are proud to introduce our Tandem Line Extrusion Line, a state-of-the-art solution for advanced extrusion needs. Designed to meet the highest standards of quality, efficiency, and versatility, our Tandem Line Extrusion Line is the ideal choice for a wide range of applications, from simple to complex, and from small to large-scale production.

✧ High Performance

Our Tandem Line Extrusion Line is designed for high performance, delivering exceptional speed, accuracy, and output. With its powerful motors, robust components, and optimized design, our line can handle even the most demanding extrusion tasks with ease. Whether you need to produce large volumes of simple products or complex profiles with tight tolerances, our line can deliver outstanding results.

✧ Multifunctionality

Our Tandem Line Extrusion Line is highly versatile and can be configured to meet a wide range of production needs. With its modular design, we can customize our line to fit your specific requirements, from the type of material you use to the shape and size of the final product. Whether you need to extrude PVC, PE, PP, ABS, or other materials, our line can handle it all.

✧ Reliability

Our Tandem Line Extrusion Line is built to last, with high-quality components and a rugged construction that can withstand even the toughest production environments. We use only the best materials and components, and our line is rigorously tested to ensure that it meets our strict quality standards. Additionally, we offer comprehensive service and support to ensure that your line is always running smoothly and efficiently.

✧ Conclusion

In conclusion, our Tandem Line Extrusion Line is the ultimate solution for advanced, high-performance, multifunctional, and reliable extrusion. With its advanced technology, high performance, versatility, and reliability, our line can help you achieve your production goals and stay ahead of the competition. Contact us today to learn more about our Tandem Line Extrusion Line and how it can benefit your business.

Technical Specifications

|

Description |

Specification |

| Material |

PVC、PE、LDPE |

| Inlet copper conductor φ[mm] |

2.5~3.0 |

| Product copper conductor φ[mm] |

0.4~1.2 |

| Finished Cable [mm] |

0.9~2.0 |

| Line speed [M/min] |

1200.Max |

Characteristics

1. The production line realizes the three processes of stretching, annealing and extrusion of copper rods at the same time, which greatly reduces production costs, improves work efficiency and reduces energy consumption.

2. Integrated design of annealing and preheating and equipped with an automatic tension adjustment system to ensure that the elongation of the copper wire and the diameter of the conductor are uniform;

3. Extrusion machine adopts special machine head to ensure that the concentricity of the core wire reaches more than 95% and the high-speed series production line

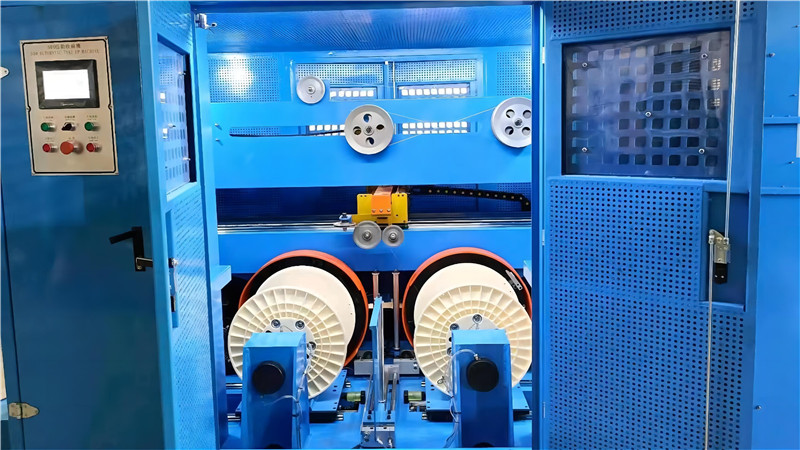

4. The extrusion process in making LAN cables (cat5, cat6) and insulative telephone cables, Composition of equipment: it consists of devices for such processes as wire drawing, annealing, pre-heating, insulation extruding, online outer diameter testing, eccentricity measurement and auto take-up

Process

Welding

Polish

Machining

Boring Mill

Assembling

Finished Product

FAQ

A: Yes, we do the following:

-Once the customer informs us that the machine is placed in the correct position, we will send mechanical and electrical engineers to start the machine.

-No-load test: After the machine is completely installed, we first carry out the no-load test.

-Load test: Usually we can produce three different wires for load test.

A: We will conduct dynamic balance test, levelness test, noise test, etc. In the production process.

After the completion of production, we usually carry out no-load operation on each machine before delivery. Welcome customers to visit.

A: We have an international universal color card RAL color card. You just need to tell us the color number. You can customize your machine to match the color matching of your factory.

Answer: Of course, this is our purpose. According to the standards that your cable should follow and your expected productivity, we will design all the equipment, molds, accessories, personnel, inputs and required materials to make documents for you.