In today’s rapidly developing technological era, wire and cable, as an important carrier of power transmission and information communication, its quality and performance are of crucial importance. And the Teflon extrusion line, as a high-end representative of wire and cable manufacturing equipment, is injecting strong impetus into the development of the wire and cable industry with its excellent performance and technical advantages.

The Teflon extrusion line has advanced technical parameters. Taking the LSHF type as an example, different models show precise performance configurations. For model 70, the power is 90KW, the output is 37Kg/H, and the rotation speed is 140rpm; for model 80, the power is 80KW, the output is 55Kg/H, and the rotation speed is 170rpm; for model 90, the power is 70KW, the output is 75Kg/H, and the rotation speed is 240rpm; for model 100, the power is 70KW, the output is 90Kg/H, and the rotation speed is 280rpm; for model 120, the power is 65KW, the output is 132Kg/H, and the rotation speed is 440rpm; for model 150, the power is 55KW, the output is 160Kg/H, and the rotation speed is 680rpm; for model 200, the power is 50KW, the output is 200Kg/H, and the rotation speed is 960rpm.

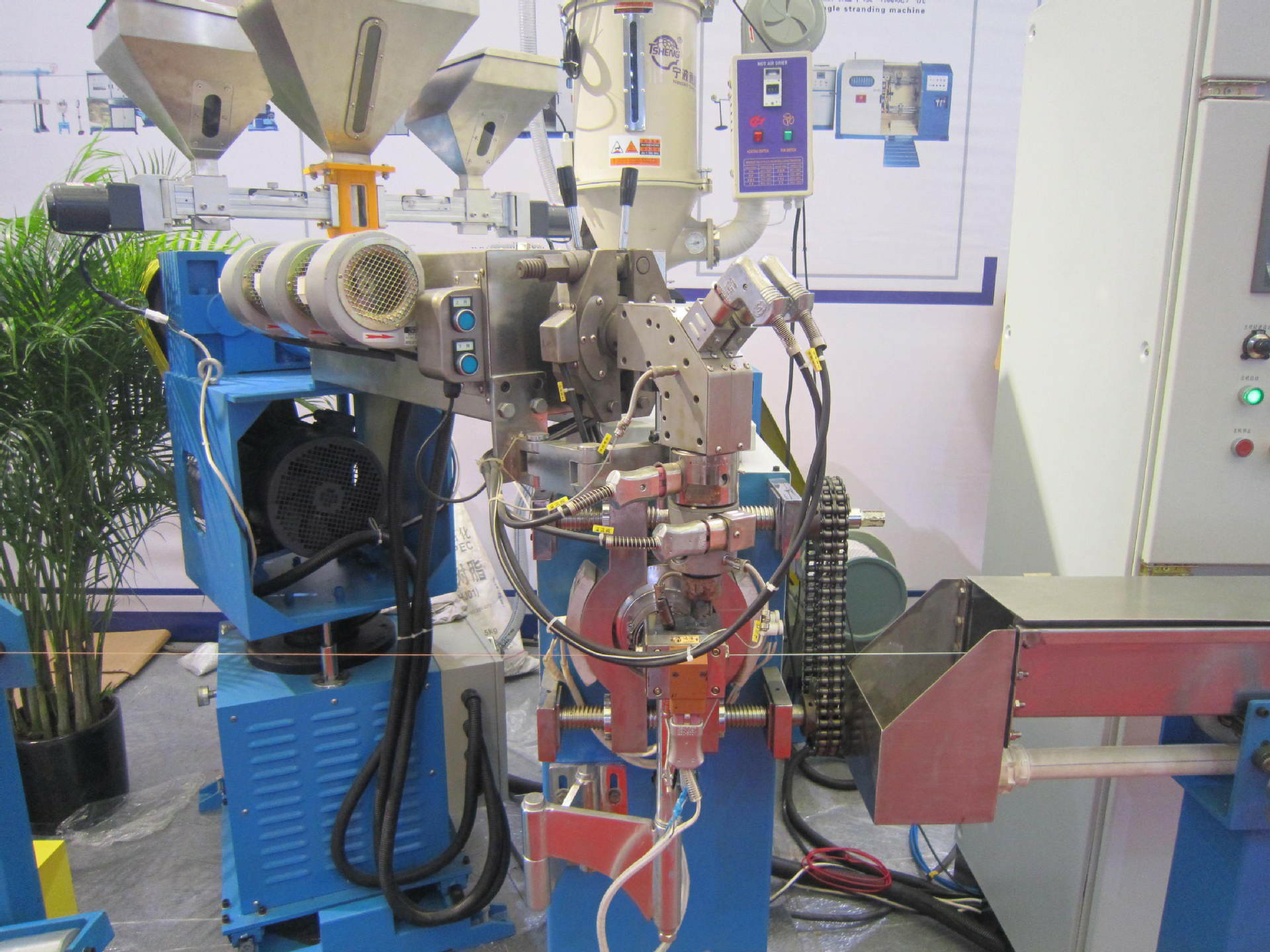

In terms of usage methods, the Teflon extrusion line, through precise temperature control, pressure regulation, and extrusion speed control, ensures that the Teflon material can be evenly wrapped on the wire and cable conductor to form a high-quality insulating layer. At the same time, this equipment also has the advantages of high automation and easy operation, greatly reducing the difficulty and labor intensity of manual operation. The usage experience on the Internet also shows that the Teflon extrusion line has good stability in the production process and can effectively reduce the scrap rate and improve production efficiency.

Looking forward to the future market, with the continuous progress of technology and the increasing demand for high-quality wire and cable, the market prospect of the Teflon extrusion line is very broad. On the one hand, with the rapid development of fields such as new energy vehicles, aerospace, and electronic communications, the demand for high-performance wire and cable will continue to grow. And Teflon material has excellent properties such as high temperature resistance, corrosion resistance, and wear resistance, which can meet the special requirements of wire and cable in these fields. Therefore, the application of Teflon extrusion lines in these fields will become more and more extensive. On the other hand, with the continuous improvement of environmental awareness, people’s demand for green and environmentally friendly wire and cable is also gradually increasing. The Teflon extrusion line can achieve low energy consumption and low pollution in the production process, which meets environmental protection requirements and will also provide strong support for its development in the future market.

For cable factories, the Teflon extrusion line has important demand value. First of all, this equipment can produce high-quality wire and cable products and improve the market competitiveness of enterprises. Taking the Teflon extrusion line of LSHF type as an example, its precise parameter configuration can ensure that the produced wire and cable has stable performance and high-quality insulating layer. Secondly, the high-efficiency production capacity of the Teflon extrusion line can meet the increasing order demand of cable factories and improve the production efficiency of enterprises. In addition, the stability and reliability of this equipment can also reduce the maintenance cost and production risk of enterprises.

In short, as a representative of high-end wire and cable manufacturing, the Teflon extrusion line has become an indispensable important equipment in the wire and cable industry with its advanced technical parameters, efficient usage methods, and broad market prospects. In the future development, it is believed that the Teflon extrusion line will continue to play its advantages and make greater contributions to the development of the wire and cable industry.

Post time: Oct-11-2024