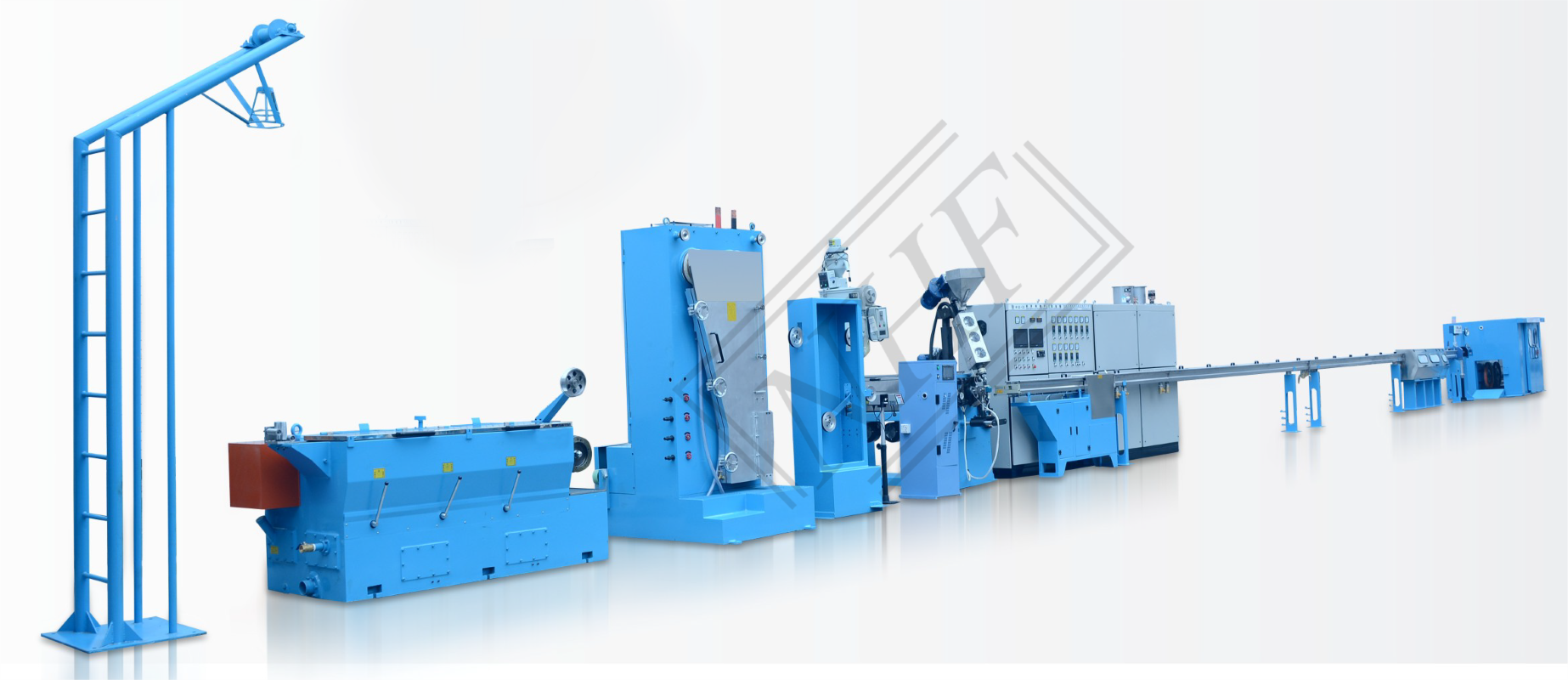

In today’s era of rapid technological development, wire and cable, as important carriers of power transmission and information communication, their quality and production efficiency are of crucial importance. The tandem extrusion production line is gradually becoming the mainstay in the field of wire and cable manufacturing with its excellent performance and efficient production capacity.

This tandem extrusion production line performs outstandingly in terms of applicable materials. It can be used for various common materials such as PVC, PE, and LDPE, providing a wide range of choices for wire and cable manufacturers. Its inlet copper conductor diameter is 5 – 3.0mm, and the drawn copper conductor diameter is between 0.4 – 1.2mm, which can meet the production needs of different specifications of wire and cable. At the same time, the finished product diameter is in the range of 0.9 – 2.0mm, ensuring product diversity.

In terms of operating speed, the production line speed is as high as 1200M/min. This astonishing speed greatly improves production efficiency and shortens the production cycle. Compared with traditional production equipment, the tandem extrusion production line can produce more high-quality products in a shorter time, winning time and market competitive advantages for enterprises.

Looking forward to the future market, with the continuous development of the global economy and the continuous progress of technology, the demand for wire and cable will continue to grow. Especially in the rapid development of fields such as new energy, communications, and transportation, the demand for high-quality and high-performance wire and cable will be even more urgent. The tandem extrusion production line is bound to occupy an important position in the future market with its efficient and stable production capacity.

For cable factories, this equipment has many advantages. First of all, its high-speed operating speed can meet the growing market demand and improve the production efficiency and production capacity of enterprises. Secondly, a wide range of applicable materials can reduce the production cost of enterprises and improve the competitiveness of products. In addition, stable production performance and high-quality finished product output can establish a good brand image for enterprises and win the trust and market share of customers.

In conclusion, the tandem extrusion production line is leading the wire and cable industry towards a more efficient and intelligent future with its excellent performance, efficient production capacity, and broad market prospects. It is believed that in the near future, this equipment will play an even more important role in the field of wire and cable manufacturing and make greater contributions to promoting the development of the industry.

Post time: Oct-11-2024