In today’s era of rapid digital development, the importance of network communication is self-evident. As a key infrastructure for network communication, the quality and production efficiency of network cables are crucial for meeting the growing network demand. The network cable sheath extrusion production line, as an important part of wire and cable manufacturing equipment, is providing strong support for the development of network communication with its excellent performance and efficient production capacity.

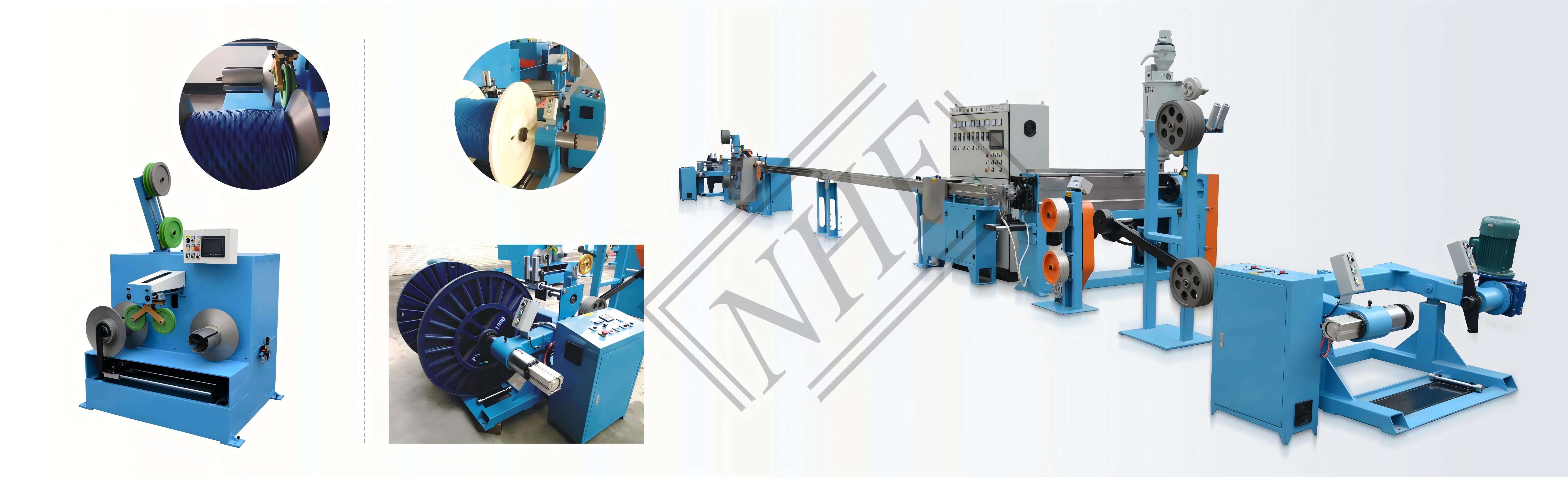

This network cable sheath extrusion production line has two models, namely WE050+30 and WE065+35, providing diverse choices for different production scales. Its screw parameters are carefully designed, with a length-to-diameter ratio of 28:1 and a compression ratio between 2.7 and 3.2. The material is 38CrMoAIA, which undergoes vacuum nitriding heat treatment, surface grinding, chrome plating, and polishing, ensuring the stability of the production process and the high quality of products.

In terms of power, the main extruder powers are 10HP and 30HP respectively, and the capstan powers are 3HP and 5HP respectively, which can meet the needs under different production speeds. The twisting distances are 50KG/H and 100KG/H respectively, and the maximum output can reach MAX400kg and MAX900kg, fully demonstrating its powerful production capacity. The maximum line speeds are 800M/MIN and 1200M/MIN respectively. The high-efficiency operating speed greatly improves production efficiency and shortens the production cycle.

The pay-off type is swinging bucket line, realizing non-stop reel change, which greatly improves the continuity of production. The take-up tension is adjustable to ensure that the pulled wire does not deform and guarantees the quality of products. The take-up type adopts a biaxial automatic take-up machine with plate change, which can realize non-stop and non-slow-down plate change. The servo motor is positioned, and the row spacing can be set arbitrarily, further improving the degree of automation and flexibility of production.

Looking forward to the future market, with the popularization of 5G technology and the rapid development of the Internet of Things, the demand for network cables will continue to grow. The network cable sheath extrusion production line will play a key role in meeting this huge demand. The demand for this equipment by cable factories will also increase day by day. On the one hand, the high-efficiency operating speed and high output can meet the large demand for network cables in the market; on the other hand, advanced technology and automation functions can reduce production costs and improve production efficiency and product quality.

In short, the network cable sheath extrusion production line provides a solid guarantee for the development of network communication with its excellent performance, high-efficiency operating speed, and powerful production capacity. In the future, this equipment will continue to play an important role and help the network communication industry move towards a more brilliant tomorrow.

Post time: Oct-17-2024