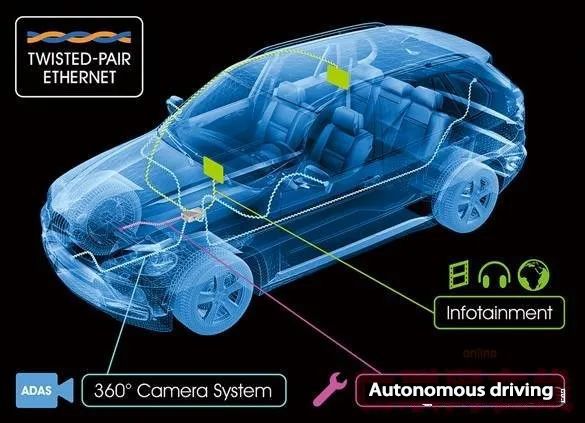

Today, the automotive industry is steadily developing under the leadership of various cutting-edge technologies. With tremendous advances in advanced driver assistance systems (ADAS), infotainment systems, and autonomous driving technology, the need for bandwidth in modern cars is also increasing. Ever-changing capabilities and emerging technologies create massive data demands, and it's imperative to process data in new ways. In the past, the application needs of traditional cars were limited to chassis control systems or body control systems, requiring only a data transmission capacity of thousands of bits per second (kbps). Today, smart cars are equipped with a large number of sensors, high-end infotainment systems, and navigation control systems based on artificial intelligence (AI) and machine learning (ML), and multiple LIDAR, RADAR, and camera modules generate terabytes of data, resulting in a significant increase in complexity. Therefore, it is imperative to leverage automotive Ethernet for high-speed, reliable, and ultra-low-latency connectivity.

Technical requirements for automotive Ethernet cables (without connectors).

The OPEN Alliance specifications (TC2 100Mbps, TC9 1000Mbps) very clearly describe the requirements for automotive Ethernet cables without connectors. The OPEN Alliance has defined the basic requirements for the required cables – the relevant performance parameters (values based on different target rates):

Impedance Z —> nominal 100Ohm for different tolerance ranges

Insertion loss IL—a smooth curve > different rate levels—depends on frequency

Return loss RL —> rate requirements depending on the frequency

Balancing performance LCL1 and LCTL2—> rates and cable design depends on the requirements of different frequencies

Coupling attenuation—> applies only to shielded cables

Shielding Effectiveness—> applies only to shielded cables

Automotive Ethernet cable head enterprise, LEONI China

LEONI is currently a leader in the automotive cable industry, most of the current cable standards are based on its defined specification protocols, it has long joined OPEN, IEEE3 and SAE4 and other alliance organizations, and cooperated with alliance members to develop 100Mbit/s and 1Gbit/s automotive Ethernet cables. LEONI Dacar is LEONI's automotive data cable brand, which mainly includes coaxial and multi-core data cables, LEONI automotive Ethernet cable because of its data characteristics requirements are also included in the Dacar series, LEONI Dacar series involves different data applications in the car, at present LEONI Dacar 100 Gigabit and Gigabit Ethernet products have been equipped and well used in many models of the global German, American, independent brands and other OEMs. LEONI doesn't stop there, Lenny is committed to going beyond that standard. LEONI's Dacar Ethernet cables define transmission characteristics such as mode conversion loss requirements for unshielded cables. The sheathed cable design ensures that the harness is installed with minimal adverse effects under conditions such as aging, impurities and humidity. For EMC-sensitive installations, LEONI offers the use of shielded LEONI Dacar Ethernet cables. These cables are already mass-produced and used in panoramic camera systems.

Ethernet marketFuture market

Because Ethernet was invented too early, the transmission of real-time information was not considered. With the large number of audio and video entertainment entering the cockpit, the number of ECUs and the demand for computing power of ECUs have shown explosive growth, which is more obvious in the ADAS era and the upcoming driverless era, and the demand for computing bandwidth has also begun to explode. This has caused a large increase in the cost of automotive electronic systems, on the one hand, the increase in the number and quality of ECU systems, because of distributed computing, a large number of computing resources are wasted, and we are talking about vehicle Ethernet using a single pair of unshielded cables and smaller and more compact connectors, using unshielded twisted pair can support 15m transmission distance (for shielded twisted pair can support 40m), this optimization processing makes automotive Ethernet can meet vehicle EMC requirements. Reducing in-vehicle connectivity costs by up to 80% and wiring weight in the car by up to 30%, the PHY of 100M Automotive Ethernet adopts 1G Ethernet technology to enable two-way communication on a single pair by using echo cancellation. Conventional PoE is designed for Ethernet with 4 pairs of cables, so PoDL was developed specifically for automotive Ethernet to provide 12VDC or 5VDC supply voltage for the normal operation of the ECU of the electronic control unit on one pair of cables. Of course, the need for bandwidth is also a factor, and various sensors, especially lidar and high-resolution cameras, must transmit data using Ethernet.

Automotive Ethernet is a peer-to-peer technology in which each electrical node is connected sequentially. A switch is deployed in the system that helps establish communication between multiple ECUs and route traffic to various other units in the network. IEEE standardizes the technology through 100BASE-T1 and 1000BASE-T1 automotive-proprietary Ethernet standards. An important advantage of automotive Ethernet is that it is more cost-effective than other protocols. Previous generations such as CAN only provide 10Mb/s throughput, while automotive Ethernet can provide a basic communication rate of 100Mb/s from the start. Compared to traditional cable harnesses, automotive Ethernet uses ultra-lightweight and efficient cabling to save space, reduce costs, and reduce complexity.

E-mail: francesgu1225@hotmail.com

E-mail: francesgu1225@gmail.com

WhatsAPP: +8618689452274

Post time: Jul-19-2023