- Dongguan NHF Machinery Co., Ltd.

- francesgu1225@hotmail.com

- +8618689452274

For a result of ours specialty and repair consciousness, our business has won a very good name among the clients all around the globe for Manufacturer for High Output PVC Extruder for Cable Wire Masterbatch Plastic Machine, First business, we learn each other. Further business, the trust is getting there. Our company always at your service at any time.

For a result of ours specialty and repair consciousness, our business has won a very good name among the clients all around the globe for Twin Screw Extruder and Plastic Extruder, Our Company has skilled engineers and technical staff to answer your questions about maintenance problems, some common failure. Our product quality assurance, price concessions, any questions about the merchandise, Make sure you feel free to contact us.

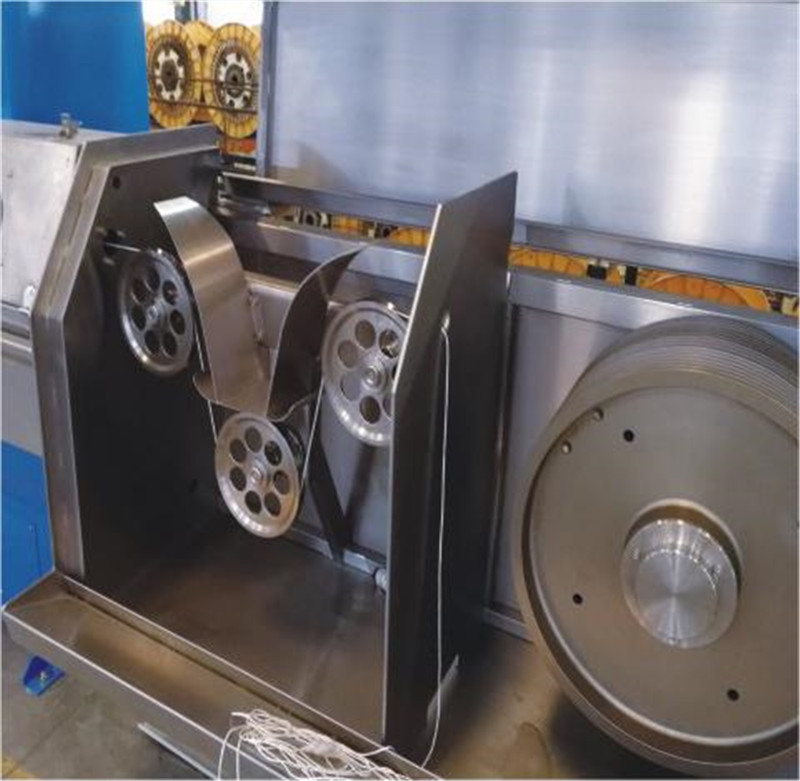

The High Output Cable Insulation Extrusion Line is built on advanced technology that leverages the latest developments in cable extrusion. It features a precision extrusion head that ensures consistent insulation thickness and diameter, while its advanced control system provides real-time monitoring and adjustment of process parameters.

The High Output Cable Insulation Extrusion Line is designed to deliver high-performance insulation that meets the most demanding industry standards. It is capable of producing a wide range of insulation materials, including PVC, XLPE, and LSZH, with excellent electrical and mechanical properties.

The High Output Cable Insulation Extrusion Line is a multifunctional system that can be customized to meet the specific needs of cable manufacturers. It can be configured to produce a range of cable types, including power cables, communication cables, and optical fiber cables, with varying insulation thicknesses and diameters.

The High Output Cable Insulation Extrusion Line is a reliable and durable system that is built to withstand the rigors of continuous operation. It features a robust frame and high-quality components that ensure long-lasting performance, while its advanced control system provides real-time monitoring and alerts for any potential issues.

The High Output Cable Insulation Extrusion Line is a state-of-the-art system that offers advanced technology, high performance, multifunctionality, and reliability. It is a versatile and efficient solution for cable manufacturers looking to produce high-quality cable insulation that meets the most demanding industry standards. With its precision extrusion head, advanced control system, and durable construction, the High Output Cable Insulation Extrusion Line is the perfect choice for any cable manufacturer looking to improve their extrusion capabilities.

Technical Specifications

|

Model |

Inlet specification |

PVC/LDPE |

||

|

Motor Power |

Max. Output |

Screw Speed |

||

|

NHF |

Section |

[KW] |

[Kg/H] |

rpm |

|

35 |

0.4-0.9mm |

7.5 |

30 |

150 |

|

50 |

0.5-1.2mm |

15 |

90 |

140 |

|

60 |

0.8-2.0mm |

18.5 |

180 |

125 |

|

Model |

Inlet specification |

MDPE/HDPE/XLPE |

||

|

Motor Power |

Max.Output |

Screw Speed |

||

|

NHF |

Section |

[KW] |

[Kg/H] |

rpm |

|

35 |

0.4-0.9mm |

11 |

30 |

150 |

|

50 |

0.5-1.2mm |

18.5 |

50 |

80 |

|

60 |

0.8-2.0mm |

22 |

105 |

75 |

|

Model |

Inlet specification |

LSZH |

||

|

Motor Power |

Max.Output |

Screw Speed |

||

|

NHF |

Section |

[KW] |

[Kg/H] |

rpm |

|

50 |

0.5-1.2mm |

18.5 |

70 |

90 |

|

60 |

0.8-2.0mm |

22 |

140 |

90 |

Characteristics

1. This equipment is used for all kinds of PVC,HDPE, XLPE, TPU, LSHF and other electronic wire and core wire extrusion.

2. PVCLDPE, extrusion materials are shared with one BM type system. Our advanced design of sere gives largest output when using PVC or LDPE or LSHF material.

3. The extruder can work with LSHF, NYLON and TPU as well by using a different screw design.

Process

Welding

Polish

Machining

Boring Mill

Assembling

Finished Product

FAQ

Q: Do you provide installation and commissioning?

A: Yes, we do the following:

-Once the customer informs us that the machine is placed in the correct position, we will send mechanical and electrical engineers to start the machine.

-No-load test: After the machine is completely installed, we first carry out the no-load test.

-Load test: Usually we can produce three different wires for load test.

Q: How do you check before delivery?

A: We will conduct dynamic balance test, levelness test, noise test, etc. In the production process.

After the completion of production, we usually carry out no-load operation on each machine before delivery. Welcome customers to visit.

Q: Can the color of the device be customized?

A: We have an international universal color card RAL color card. You just need to tell us the color number. You can customize your machine to match the color matching of your factory.

Q: Can you customize it in the main factory?

Answer: Of course, this is our purpose. According to the standards that your cable should follow and your expected productivity, we will design all the equipment, molds, accessories, personnel, inputs and required materials to make documents for you.For a result of ours specialty and repair consciousness, our business has won a very good name among the clients all around the globe for Manufacturer for High Output PVC Extruder for Cable Wire Masterbatch Plastic Machine, First business, we learn each other. Further business, the trust is getting there. Our company always at your service at any time.

Manufacturer for Twin Screw Extruder and Plastic Extruder, Our Company has skilled engineers and technical staff to answer your questions about maintenance problems, some common failure. Our product quality assurance, price concessions, any questions about the merchandise, Make sure you feel free to contact us.