- Dongguan NHF Machinery Co., Ltd.

- francesgu1225@hotmail.com

- +8618689452274

We insist around the principle of enhancement of ‘High good quality, Performance, Sincerity and Down-to-earth working approach’ to provide you with superb assistance of processing for Manufacturer for Automatic PP/PE/PVC/HDPE Insulating Sheath Cable Extruder Extrusion Machine Line for Wire Power Cable Umbilical, Because we stay within this line about 10 years. We got very best suppliers aid on quality and cost. And we had weed out suppliers with poor high-quality. Now lots of OEM factories cooperated with us too.

We insist around the principle of enhancement of ‘High good quality, Performance, Sincerity and Down-to-earth working approach’ to provide you with superb assistance of processing for Cable Equipment and Cable Extrusion Machine, With the highest standards of product quality and service, our items have been exported to more than 25 countries like the USA, CANADA, GERMANY, FRANCE, UAE, Malaysia and so on.We have been very pleased to serve customers from all over the world!

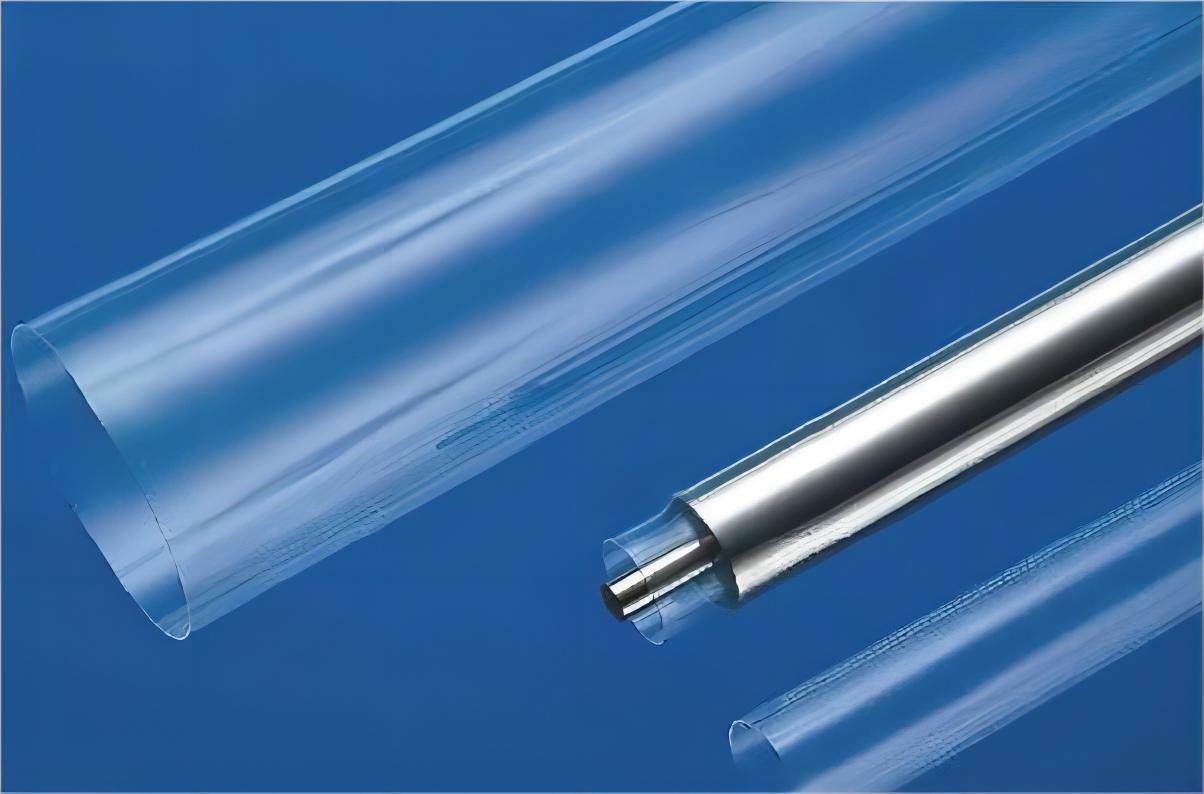

Polyperfluoroethylene (FEP, F46) transparent tube FEP transparent tube use Liquid crystal manufacturing device Single-end light-emitting single-core optical fiber tube Heat exchanger, steam piping High-purity reagent delivery tube Various corrosive media (harsh solvents) pipelines Various frequency wire and cable sheaths, slot insulation tubes Slot insulation tube for submersible motor Air conditioning wiring harness assembly tube All-inclusive Fluoroplastic O-ring Seal Tube Use characteristics High and low-temperature resistance: -200–200 ℃ Non-sticky, fight the water, fight oil Electrical reliability, high insulation he dielectric constant viscosity at high

Applications: It can be used to convey high-clean fluids, chemicals, dairy products, cosmetics, etc. It can also be used for the protection of heat exchangers and cables, and is widely used in various industrial fields. It has excellent heat resistance, non-adhesion resistance, chemical resistance, electrical insulation, etc. Commonly used in the following industries: chemical facilities / semiconductor manufacturing equipment / food manufacturing equipment / physical and chemical equipment / auto parts / chemical liquid, fuel, oil, steam transmission pipeline / electrical insulation cover / others Working temperature: -40°C~+260°C

Hose features:

1. It has excellent heat resistance, chemical resistance, sliding property, non-adhesion, current insulation and weather resistance.

2. The color varies according to the size and size, it is translucent ~ milky white.

3. It is also possible to manufacture colored products (black, white, red, blue, green, yellow, orange, gray)

Hose features:

1. It has excellent insulation, chemical resistance, low dissolution, and inner surface smoothness.

2. The color is transparent, and it is easy to confirm the fluid.

Construction: Type FS is smooth tube manufactured from FEP material.

Temp. Range: -40°C and 200°C.

Applications: For transfer of high purity products, chemicals, dairy and cosmetic products. Widely used in petrochemical, gold processing machinery, electronics, medical and pharmaceutical, anti-corrosion pipes and equipment and

other industrial areas.

Scope of application:

PVDF pipe (polyvinylidene fluoride pipe), the molecular chain is closely arranged, has strong hydrogen bonds, natural flame resistance, crystallinity 65%~78%, long-term use temperature -40~150 °C. Its outstanding features are high mechanical strength, good radiation resistance, and long-term outdoor use without maintenance. It has good chemical stability, is not corroded by acids, alkalis, strong oxidants and halogens at room temperature, and is widely used in petrochemical, electronic and electrical, steel mill pickling, acid and alkali liquid transportation.

Hose features:

1. Excellent chemical resistance, not corroded by acids, alkali strong oxidants and halogens at room temperature.

2. High impact strength, wear resistance, creep resistance, high mechanical strength and good toughness.

3. Good heat resistance, non-combustibility, long-term use temperature -40~150 °C, and high dielectric strength.

4. It has outstanding weather aging resistance, ozone resistance, ultraviolet and nuclear radiation resistance.

Technical Specifications

|

Temperature Correction Facto |

|||||||||||||||||||

|

-60 |

-40 |

-20 |

0 |

20 |

50 |

100 |

120 |

150 |

180 |

200 |

220 |

250 |

260 |

||||||

|

1.0 |

1.0 |

1.0 |

1.0 |

1.0 |

1.0 |

1.0 |

0.93 |

0.93 |

0.85 |

0.85 |

0.77 |

0.77 |

0.70 |

||||||

|

|

|||||||||||||||||||

|

Part |

Size |

Internal |

Wall |

Outside |

Min |

SAE 100R14 |

SAE 100R14 |

Vacuum |

|||||||||||

|

316 Braid |

304 Braid |

Inch |

Min |

Max |

mm |

Min |

Max. |

mm |

kPa |

Bar |

kPa |

Bar |

mm hg |

||||||

|

PTFE6S-03 |

PTFE4S-03 |

1/8″ |

3.3 |

3.5 |

0.76 |

5.84 |

6.35 |

38 |

20700 |

207 |

82800 |

828 |

711.20 |

||||||

|

PTFE6S-04 |

PTFE4S-04 |

3/16″ |

4.64 |

5.2 |

0.76 |

7.32 |

8.2 |

51 |

20700 |

207 |

82800 |

828 |

711.20 |

||||||

|

PTFE6S-06 |

PTFE45-06 |

1/4″ |

6.17 |

6.73 |

0.76 |

8.92 |

9.47 |

76 |

18098 |

180 |

72392 |

723 |

711.20 |

||||||

|

PTFE6S-08 |

PTFE45-08 |

5/16″ |

7.54 |

8.38 |

0.76 |

10.36 |

11.63 |

102 |

17236 |

172 |

68944 |

689 |

711.20 |

||||||

|

PTEE6S-10 |

PTFE45-10 |

3/8″ |

9.27 |

9.77 |

0.76 |

12.2 |

13.21 |

127 |

15513 |

155 |

62052 |

620 |

711.20 |

||||||

|

PTFE6S-11 |

PTFE4S-11 |

13/32″ |

10.08 |

10.85 |

0.76 |

13.03 |

14.19 |

133 |

13789 |

137 |

55156 |

551 |

711.20 |

||||||

|

PTFE6S-12 |

PTFE4S-12 |

1/2″ |

12.42 |

13.18 |

0.76 |

15.44 |

16.71 |

165 |

10342 |

103 |

41368 |

413 |

711.20 |

||||||

|

PTFE6S-15 |

PTFE45-15 |

5/8″ |

15.36 |

16.38 |

0.76 |

18.74 |

20.02 |

197 |

8618 |

86 |

34472 |

344 |

711.20 |

||||||

|

PTFE6S-20 |

PTFE4S-20 |

3/4″ |

18.61 |

19.38 |

0.89 |

21.59 |

22.86 |

229 |

7584 |

75 |

30336 |

303 |

508.00 |

||||||

|

PTFE6S-22 |

PTFE4S-22 |

7/8″ |

21.46 |

23.0 |

0.89 |

24.60 |

26.90 |

229 |

6894 |

68 |

27576 |

275 |

355.59 |

||||||

|

PTFE6S-25 |

PTFE4S-25 |

1″ |

24.63 |

26.16 |

0.89 |

27.80 |

29.85 |

305 |

6205 |

62 |

24820 |

248 |

355.59 |

||||||

|

PTFE6S-28 |

PTFE4S-28 |

11/8″ |

27.80 |

28.34 |

1.14 |

31.95 |

33.50 |

406 |

5171 |

51 |

20684 |

206 |

355.59 |

||||||

Process

Welding

Polish

Machining

Boring Mill

Assembling

Finished Product

FAQ

Q: Do you provide installation and commissioning?

A: Yes, we do the following:

-Once the customer informs us that the machine is placed in the correct position, we will send mechanical and electrical engineers to start the machine.

-No-load test: After the machine is completely installed, we first carry out the no-load test.

-Load test: Usually we can produce three different wires for load test.

Q: How do you check before delivery?

A: We will conduct dynamic balance test, levelness test, noise test, etc. In the production process.

After the completion of production, we usually carry out no-load operation on each machine before delivery. Welcome customers to visit.

Q: Can the color of the device be customized?

A: We have an international universal color card RAL color card. You just need to tell us the color number. You can customize your machine to match the color matching of your factory.

Q: Can you customize it in the main factory?

Answer: Of course, this is our purpose. According to the standards that your cable should follow and your expected productivity, we will design all the equipment, molds, accessories, personnel, inputs and required materials to make documents for you.

We insist around the principle of enhancement of ‘High good quality, Performance, Sincerity and Down-to-earth working approach’ to provide you with superb assistance of processing for Manufacturer for Automatic PP/PE/PVC/HDPE Insulating Sheath Cable Extruder Extrusion Machine Line for Wire Power Cable Umbilical, Because we stay within this line about 10 years. We got very best suppliers aid on quality and cost. And we had weed out suppliers with poor high-quality. Now lots of OEM factories cooperated with us too.

Manufacturer for Cable Equipment and Cable Extrusion Machine, With the highest standards of product quality and service, our items have been exported to more than 25 countries like the USA, CANADA, GERMANY, FRANCE, UAE, Malaysia and so on.We have been very pleased to serve customers from all over the world!