- Dongguan NHF Machinery Co., Ltd.

- francesgu1225@hotmail.com

- +8618689452274

Fast and excellent quotations, informed advisers to help you choose the correct product that suits all your requirements, a short manufacturing time, responsible top quality management and unique services for paying and shipping affairs for Discountable price Low Noise Silicone Rubber Cable Extrusion Machine/High Temperature Wire Production Line, We fully welcome consumers from everywhere in the world to establish stable and mutually helpful small business associations, to have a vibrant future alongside one another.

Fast and excellent quotations, informed advisers to help you choose the correct product that suits all your requirements, a short manufacturing time, responsible top quality management and unique services for paying and shipping affairs for Silicone Hose Extrusion Machine and High Temperature Wire Extruder, We adopt advanced production equipment and technology, and perfect testing equipment and methods to ensure our product quality. With our high-level talents, scientific management, excellent teams, and attentive service, our solutions are favored by domestic and foreign customers. With your support, we will build a better tomorrow!

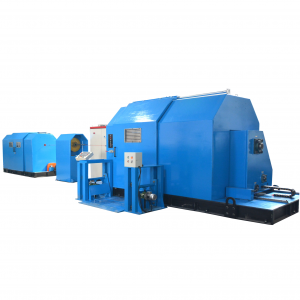

This equipment is designed for the production of special decorative wires for automobiles, low-voltage ordinary wires AV, low-voltage thin skin wires AVS, low-voltage ultra-thin skin wires AVSS, electronic irradiation PVC low-voltage wires AVS, electronic irradiation PE low-voltage wires AEX, low-voltage compressed conductor thin skin CAVS, etc. It is suitable for the production of conventional plastics such as PVC, PE, and is primarily used for the production of automobile electronic wires, core wires, etc.

1. Precision extrusion process control, ensuring an outer diameter error of ± 0.01mm, and a production line speed of 1000 meters or higher.

2. Specially equipped with a mobile vertical extrusion attachment machine or other forms of attachment machine, meeting special process technical requirements such as multi-color strip and color skin co-extrusion.

3. Equipped with advanced automotive line dedicated machine heads, ensuring various process requirements such as insulation thickness and concentricity of the product.

4. Equipped with a fast color change system, enabling continuous color change of color strips, significantly reducing the scrap rate.

5. Equipped with a precise closed-loop feedback control system, automatically controlling process parameters such as insulation outer diameter and core consistency of the wire core to ensure product quality.

6. The wire winding machine can be equipped with a microcomputer fully automatic shaking disc machine, plum blossom falling barrel wire winding machine, and dual-axis fully automatic wire winding machine to meet different wire packaging requirements.

7. Utilizes PLC and professional CNC software, industrial computer control, storage display, and correction of various process parameters, enabling comprehensive process control, adjustment, and monitoring of production line status.

| Machinery type | NHF-50+35 | NHF-70+35 | NHF-90+45 |

| Extrusion materials | PVC, PE, PP, PU, NYLON, TPEE, etc | ||

| Pay-off type | Power or passive pay-off | Power or passive pay-off | Power or passive pay-off |

| Payout spool | PN500-630 | PN500-630 | PN500-630 |

| Screw OD | φ 50+35 | φ 70+35 | φ 90+45 |

| Screw L/D | 26:01:00 | 26:01:00 | 25:01:00 |

| kg/h | 60 | 180 | 230 |

| Main motor | 20HP | 30HP | 50HP |

| Wire OD | φ 0.1-3.5 | φ 2.0-8.0 | φ 2.0-10 |

| Temperature control | 6 segments | 6 segments | 6 segments |

| Cooling device | U-shaped double layer | U-shaped double layer | U-shaped double layer |

| Towing power | 5HP | 5HP | 7.5HP |

| Storage rack | Horizontal | Horizontal | Horizontal |

| Storage length | 200 | 200 | 200 |

| Outgoing speed | MAX600 | MAX500 | MAX500 |

| Take-up type | Bouble-shaft | Bouble-shaft | Bouble-shaft |

| Take-up spool | PN500-630 | PN500-630 | PN500-630 |

| Electric control | PLC control | PLC control | PLC control |

Fast and excellent quotations, informed advisers to help you choose the correct product that suits all your requirements, a short manufacturing time, responsible top quality management and unique services for paying and shipping affairs for Discountable price Low Noise Silicone Rubber Cable Extrusion Machine/High Temperature Wire Production Line, We fully welcome consumers from everywhere in the world to establish stable and mutually helpful small business associations, to have a vibrant future alongside one another.

Discountable price Silicone Hose Extrusion Machine and High Temperature Wire Extruder, We adopt advanced production equipment and technology, and perfect testing equipment and methods to ensure our product quality. With our high-level talents, scientific management, excellent teams, and attentive service, our solutions are favored by domestic and foreign customers. With your support, we will build a better tomorrow!