- Dongguan NHF Machinery Co., Ltd.

- francesgu1225@hotmail.com

- +8618689452274

✧ Advanced Technology

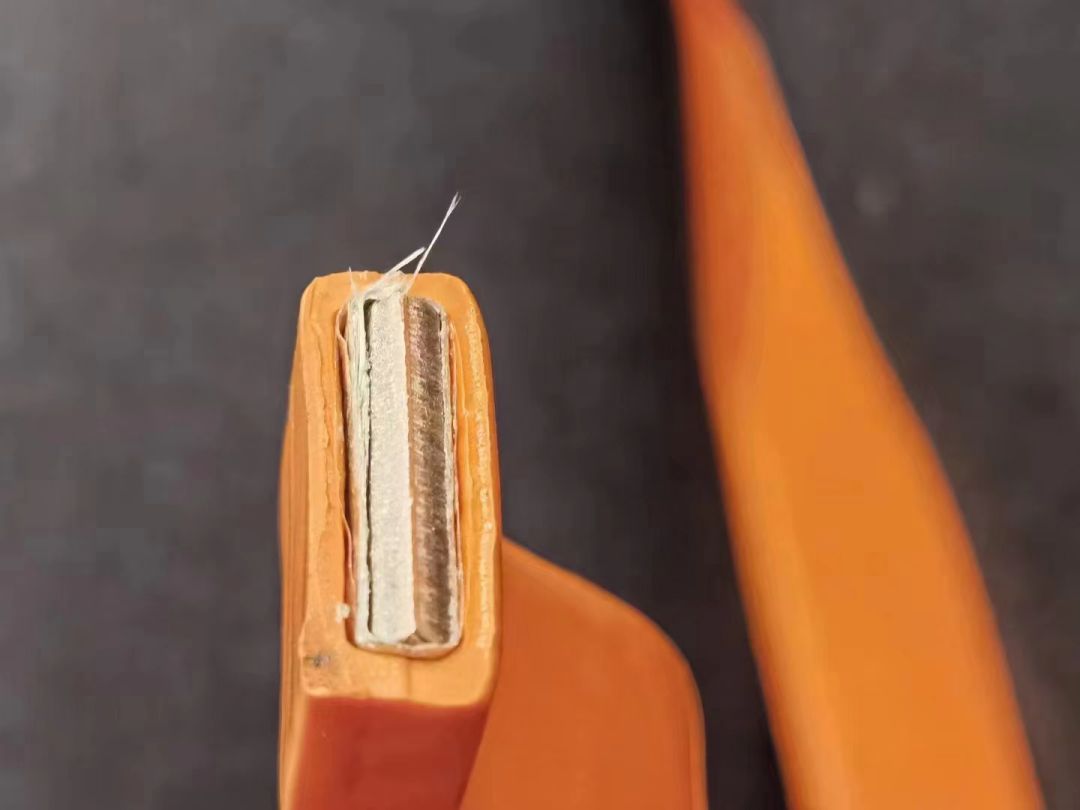

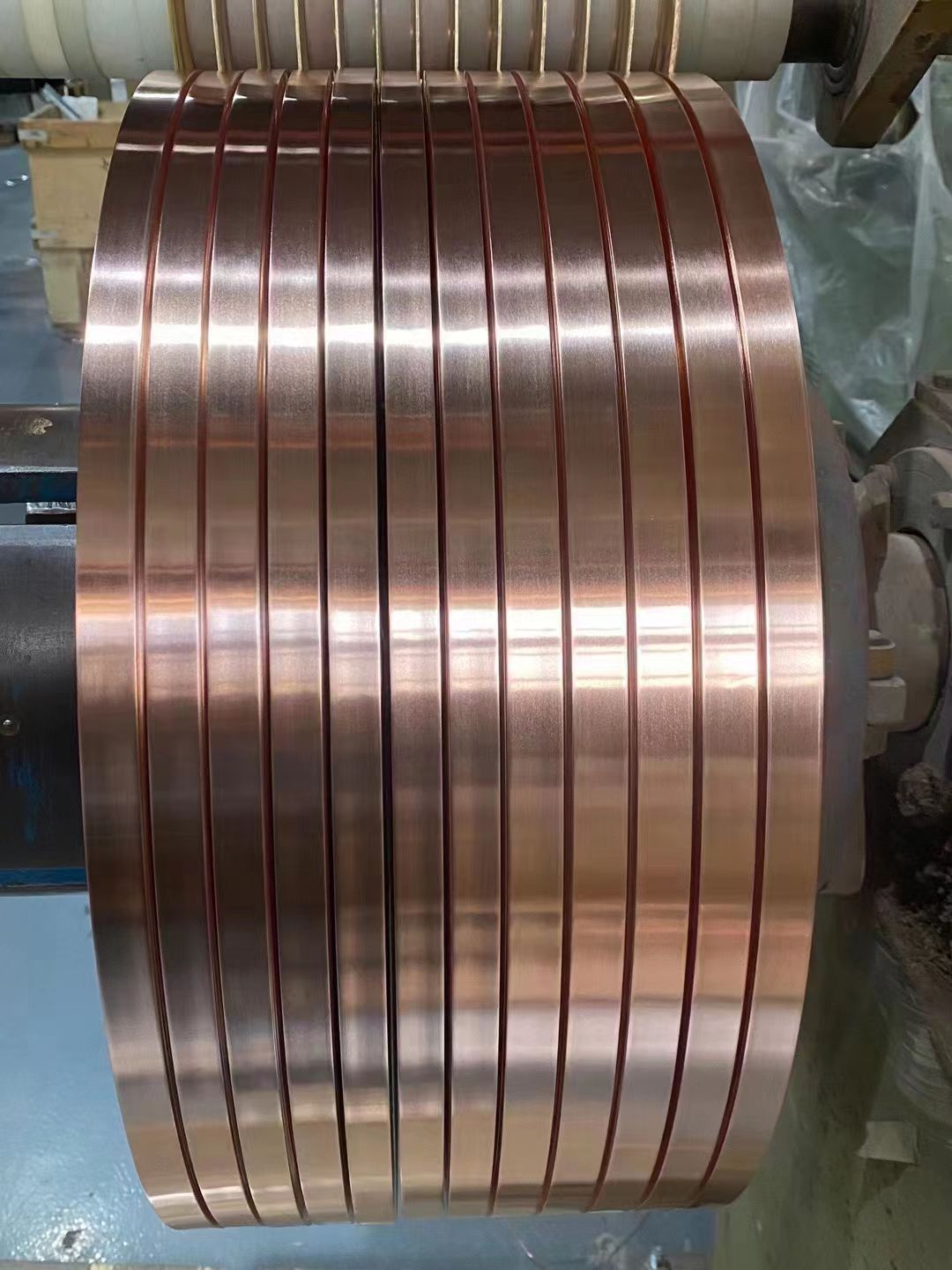

The Copper-Aluminum Strip Cladding Production Line is a high-tech manufacturing process that uses the latest technology to produce high-quality cladded strips. The line uses advanced equipment, materials, and techniques to ensure that the end product is uniform, precise, and free from defects.

✧ High Performance

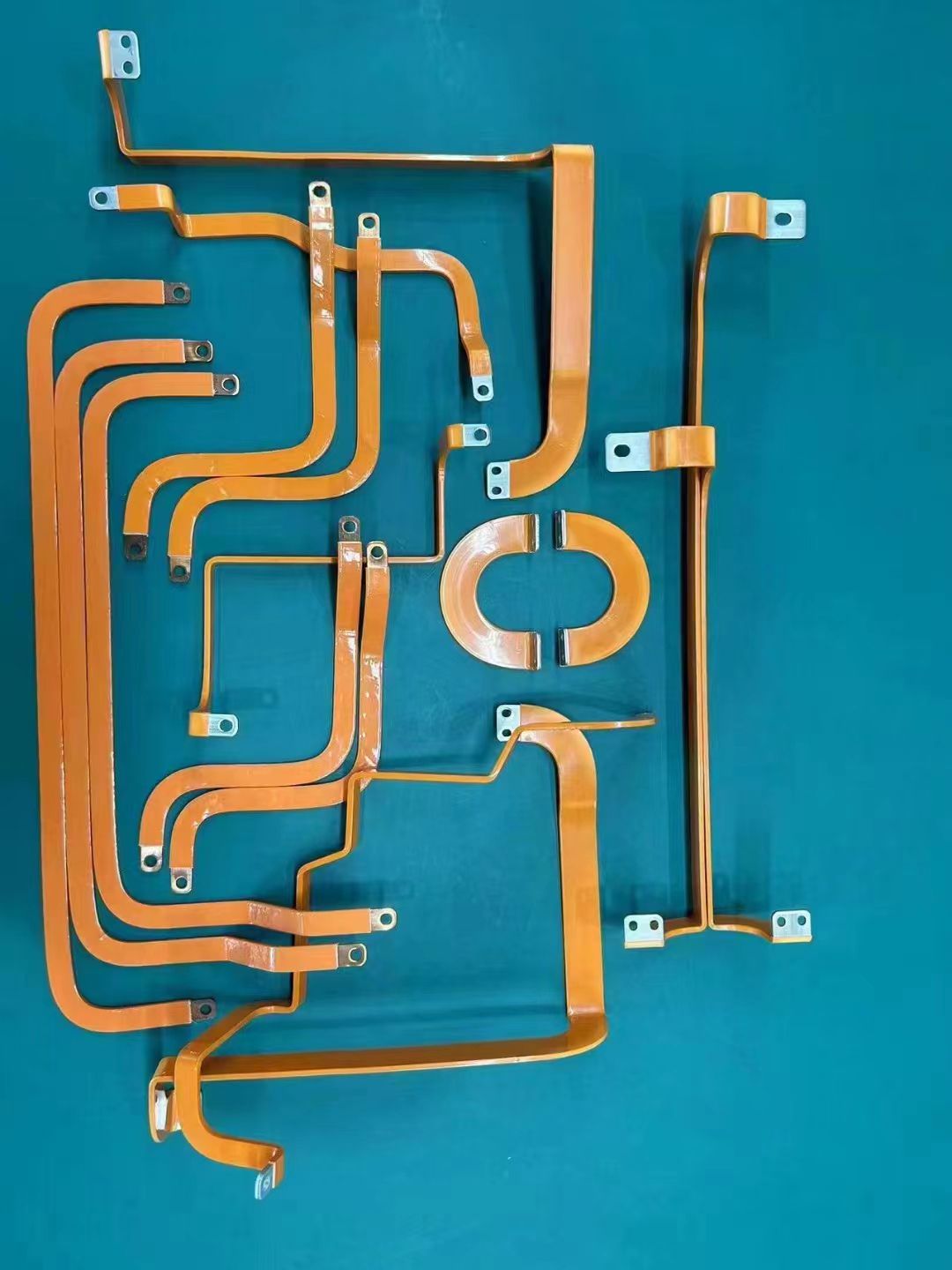

The Copper-Aluminum Strip Cladding Production Line produces strips that exhibit outstanding performance in a variety of applications. The cladded strips are characterized by high electrical conductivity, excellent thermal transfer properties, and good mechanical strength, making them ideal for use in the new energy battery industry.

✧ Multi-Functional

The Copper-Aluminum Strip Cladding Production Line is designed to produce multi-functional strips that can be used in a wide range of applications. The cladded strips can be customized to meet specific requirements, including size, shape, and composition. They can be used in the construction of battery modules, bus bars, and other components that require high electrical conductivity and efficient heat dissipation.

✧ Reliability

The Copper-Aluminum Strip Cladding Production Line is equipped with advanced automation technology that ensures consistent performance and high reliability. The line is designed with safety and efficiency in mind, reducing the risk of accidents and ensuring that the production process runs smoothly and efficiently.

✧ Conclusion

In conclusion, the Copper-Aluminum Strip Cladding Production Line is an innovative and cost-effective solution for the new energy industry. Its advanced technology, high-performance properties, multi-functional capabilities, and reliability make it an attractive option for businesses seeking to produce high-quality cladded strips that meet the requirements of the battery market. With the Copper-Aluminum Strip Cladding Production Line, businesses can reduce costs, improve efficiency and productivity, and take advantage of the latest technological advances in the industry.

Process

Welding

Polish

Machining

Boring Mill

Assembling

Finished Product

Technical Specifications

| Covering material: | XLPE/PVC/PA12. Plasticizing degree 100% |

| Cover size : | Φ thick 2~6mm wide 14~50mm; |

| Maximum wrapping speed: | Φ thick 2~6mm wide 14~50mm; |

| Center height: | 1000mm |

| Voltage: | 3 ph 380V, 50HZ |

FAQ

A: Yes, we do the following:

-Once the customer informs us that the machine is placed in the correct position, we will send mechanical and electrical engineers to start the machine.

-No-load test: After the machine is completely installed, we first carry out the no-load test.

-Load test: Usually we can produce three different wires for load test.

A: We will conduct dynamic balance test, levelness test, noise test, etc. In the production process.

After the completion of production, we usually carry out no-load operation on each machine before delivery. Welcome customers to visit.

A: We have an international universal color card RAL color card. You just need to tell us the color number. You can customize your machine to match the color matching of your factory.

Answer: Of course, this is our purpose. According to the standards that your cable should follow and your expected productivity, we will design all the equipment, molds, accessories, personnel, inputs and required materials to make documents for you.