- Dongguan NHF Machinery Co., Ltd.

- francesgu1225@hotmail.com

- +8618689452274

✧ Advanced Technology

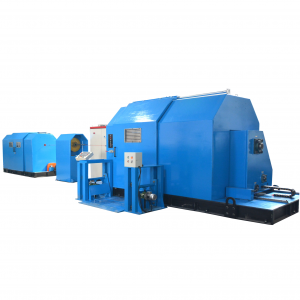

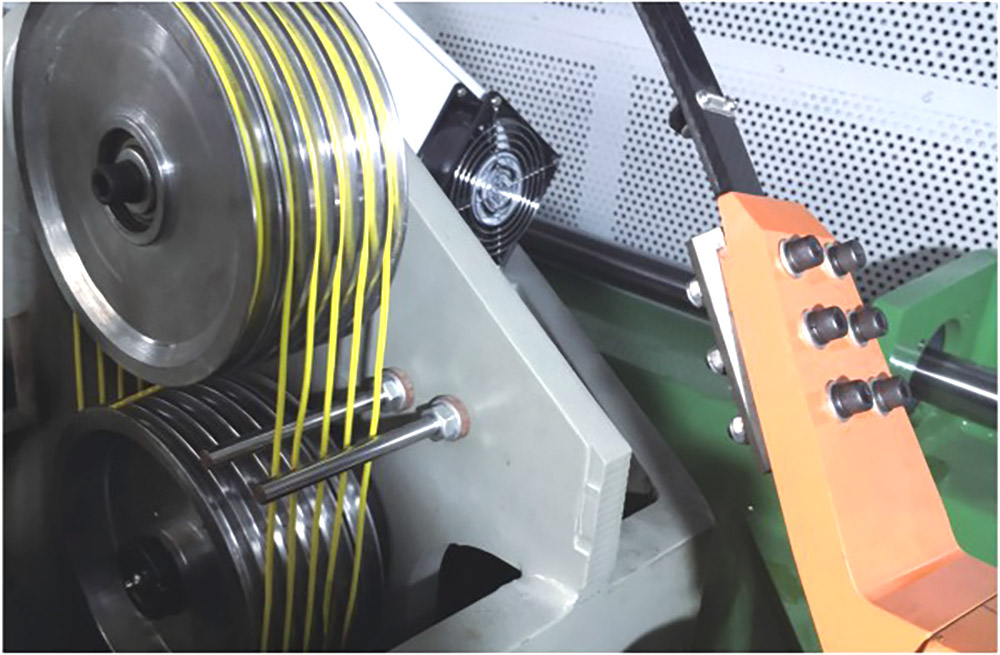

The NHF800 to 1000 Double Twist Bunching Machine is built with advanced technology that improves performance and efficiency. This machine is equipped with a state-of-the-art control system that offers accurate and precise control over the machine's operations. The advanced technology used in this machine ensures that it can handle a wide range of wire sizes, making it suitable for use in various industrial applications.

✧ High Performance

This machine offers high performance, making it an industry standard for wire twisting and bunching. It has a high rotational speed, which enables it to twist and bunch wires at a fast rate, thus reducing production time. The machine is equipped with a high-power motor that provides sufficient power for wire twisting and bunching. The NHF800 to 1000 Double Twist Bunching Machine is designed to provide consistent and high-quality results each time it is used.

✧ Multi-Functional

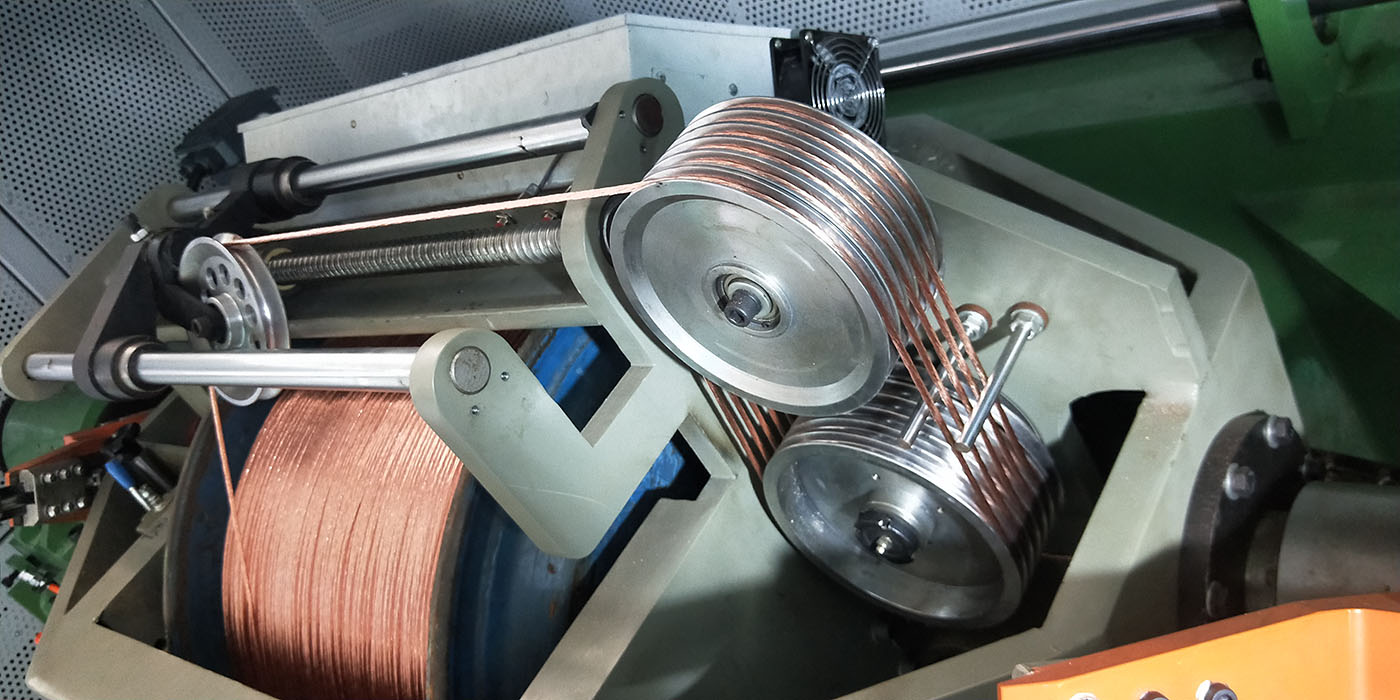

The NHF800 to 1000 Double Twist Bunching Machine is multi-functional, making it a versatile machine that can be used for various wire twisting applications. It is designed to twist and bunch different types of wires, including copper, aluminium, steel, and other materials. The machine's multi-functional capabilities make it the perfect choice for industries that require various wire twisting and bunching applications.

✧ Reliability

The NHF800 to 1000 Double Twist Bunching Machine is built with high-quality materials and components, making it reliable and durable. This machine is designed to withstand demanding industrial applications, and it can operate for long hours without experiencing breakdowns. The machine's reliability makes it the perfect choice for industries that require high-quality wire twisting and bunching equipment.

✧ Conclusion

In summary, the NHF800 to 1000 Double Twist Bunching Machine is a reliable, high-performance, multi-functional, and advanced wire twisting and bunching machine. Its state-of-the-art technology, high-quality components, and superior performance make it an industry standard for wire twisting and bunching. This machine is suitable for use in various industrial applications and is an essential piece of equipment for industries that require high-quality wire twisting and bunching operations. Choose NHF800 to 1000 Double Twist Bunching Machine for reliable, high-performance wire twisting and bunching operations.

Technical Specifications

|

Model |

NHF800C syetem setting |

NHF800D change the gear |

NHF1000C |

|

Take up [mm] |

800 |

800 |

1000 |

|

Drum load[kg] |

1000 |

1000 |

2000 |

|

Cross section [mm²] |

2.5-16 |

2.5~16 |

4~25 |

|

Rotating speed [rpm] |

1400 |

1800 |

1000 |

|

Twisting speed [tp+ m] |

2800 |

3600 |

2000 |

|

Line speed[M/min] |

150 |

180 |

150 |

|

Motor Power[KW] |

30 |

25 |

32 |

Characteristics

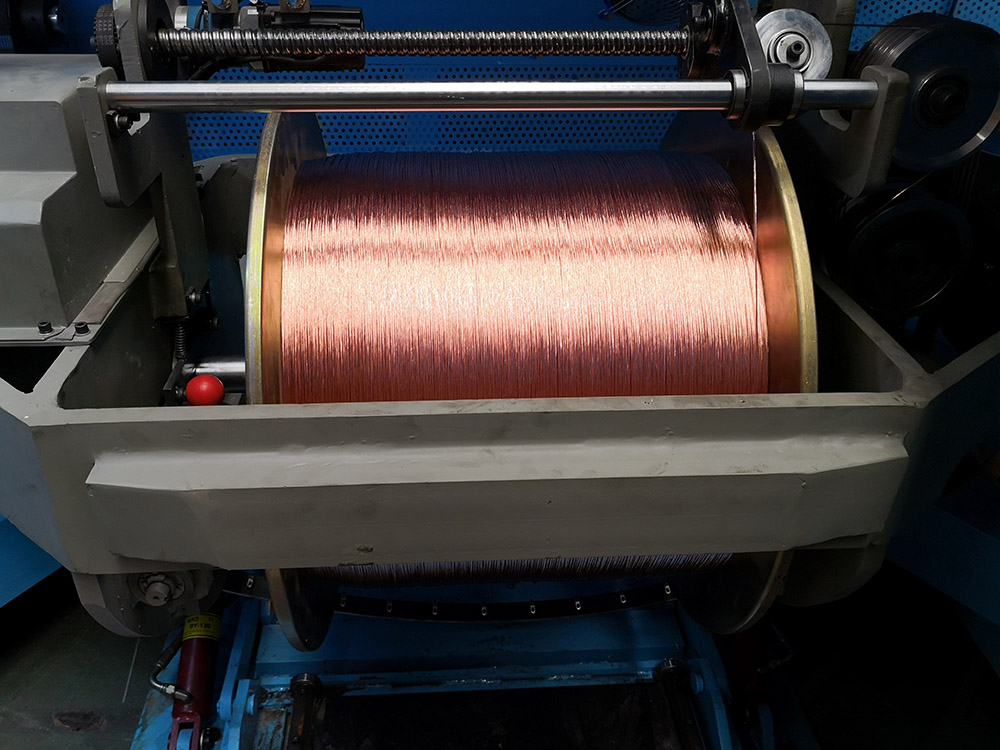

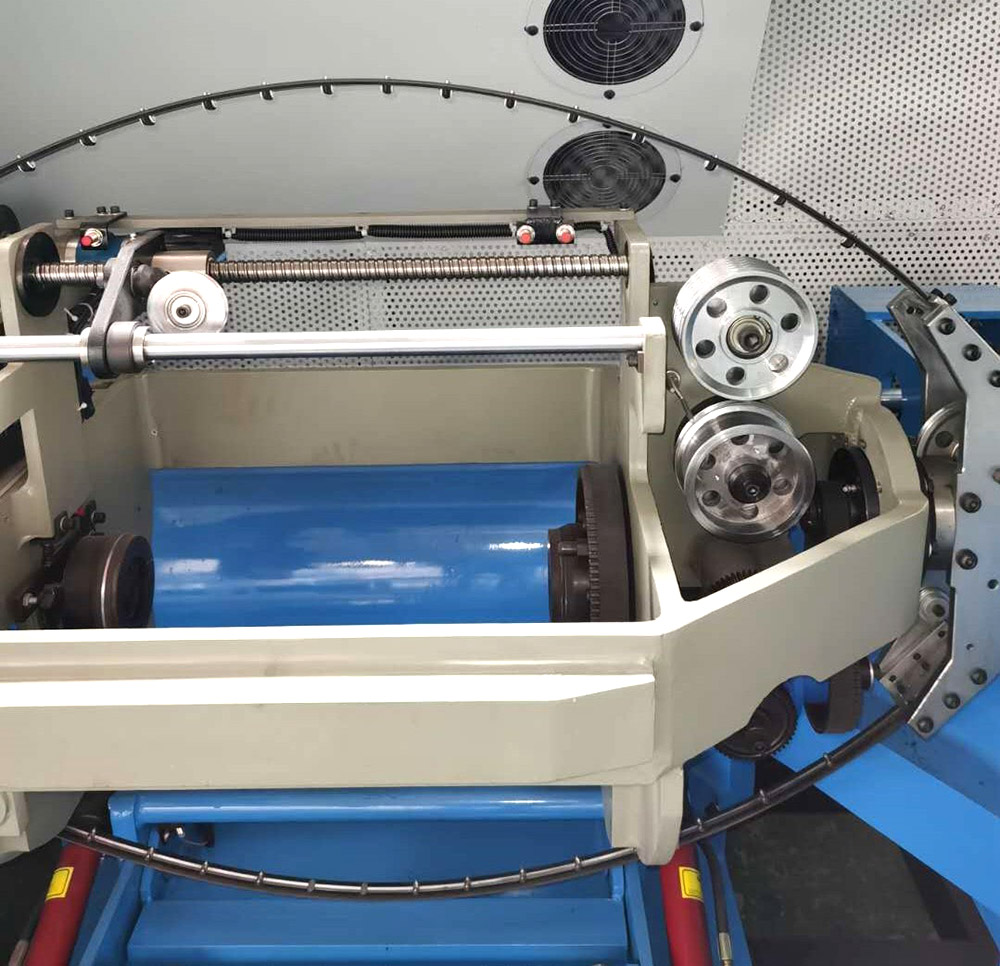

1. The servo motor takes up the wire, and the tension on the empty reel-full reel is stable without drifting, and the tension closed-loop system is optional;

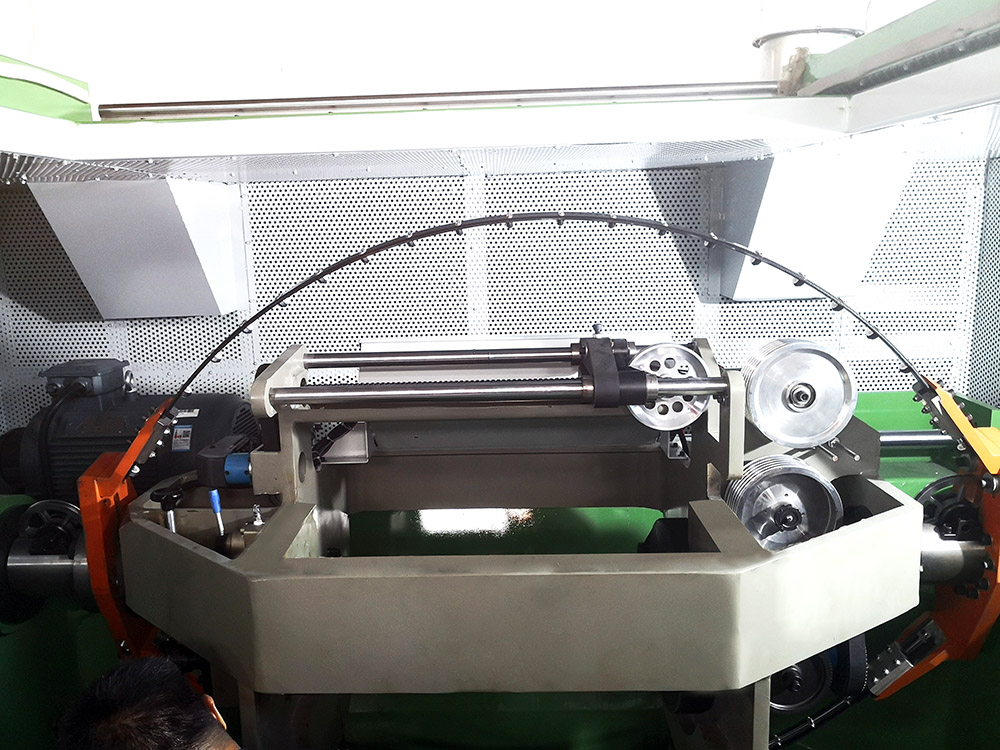

2. With the servo motor screw rod, the thrust is strong, the disk surface is flat, and the width and spacing can be adjusted online;

3. The temperature of the main shaft is monitored, and the lubricating grease is reminded according to the running time;

4. The internal meter counts the number of meters after stranding, and the production is precise and fixed-length;

5. Automatic shutdown protection function, when the reel is full or abnormal conditions occur, it will automatically stop protection to avoid equipment damage or safety accidents;

6. Touch screen control system, easy to operate, can realize parameter setting, production monitoring, fault diagnosis and other functions;

7. High efficiency and energy saving, using frequency conversion speed regulation technology, can automatically adjust the motor speed according to production needs, reduce energy consumption and improve production efficiency.

8. Suitable for the stranding of 7-19 copper wires (Class 2)aw well as for bunching of multiple fin copper wires(class 5)

9. HMl+PLC control system for pre-setting stranding lay length.twist direction and speed synchronization.

Process

Welding

Polish

Machining

Boring Mill

Assembling

Finished Product

FAQ

A: Yes, we do the following:

-Once the customer informs us that the machine is placed in the correct position, we will send mechanical and electrical engineers to start the machine.

-No-load test: After the machine is completely installed, we first carry out the no-load test.

-Load test: Usually we can produce three different wires for load test.

A: We will conduct dynamic balance test, levelness test, noise test, etc. In the production process.

After the completion of production, we usually carry out no-load operation on each machine before delivery. Welcome customers to visit.

A: We have an international universal color card RAL color card. You just need to tell us the color number. You can customize your machine to match the color matching of your factory.

Answer: Of course, this is our purpose. According to the standards that your cable should follow and your expected productivity, we will design all the equipment, molds, accessories, personnel, inputs and required materials to make documents for you.