- Dongguan NHF Machinery Co., Ltd.

- francesgu1225@hotmail.com

- +8618689452274

✧ Advanced Technology

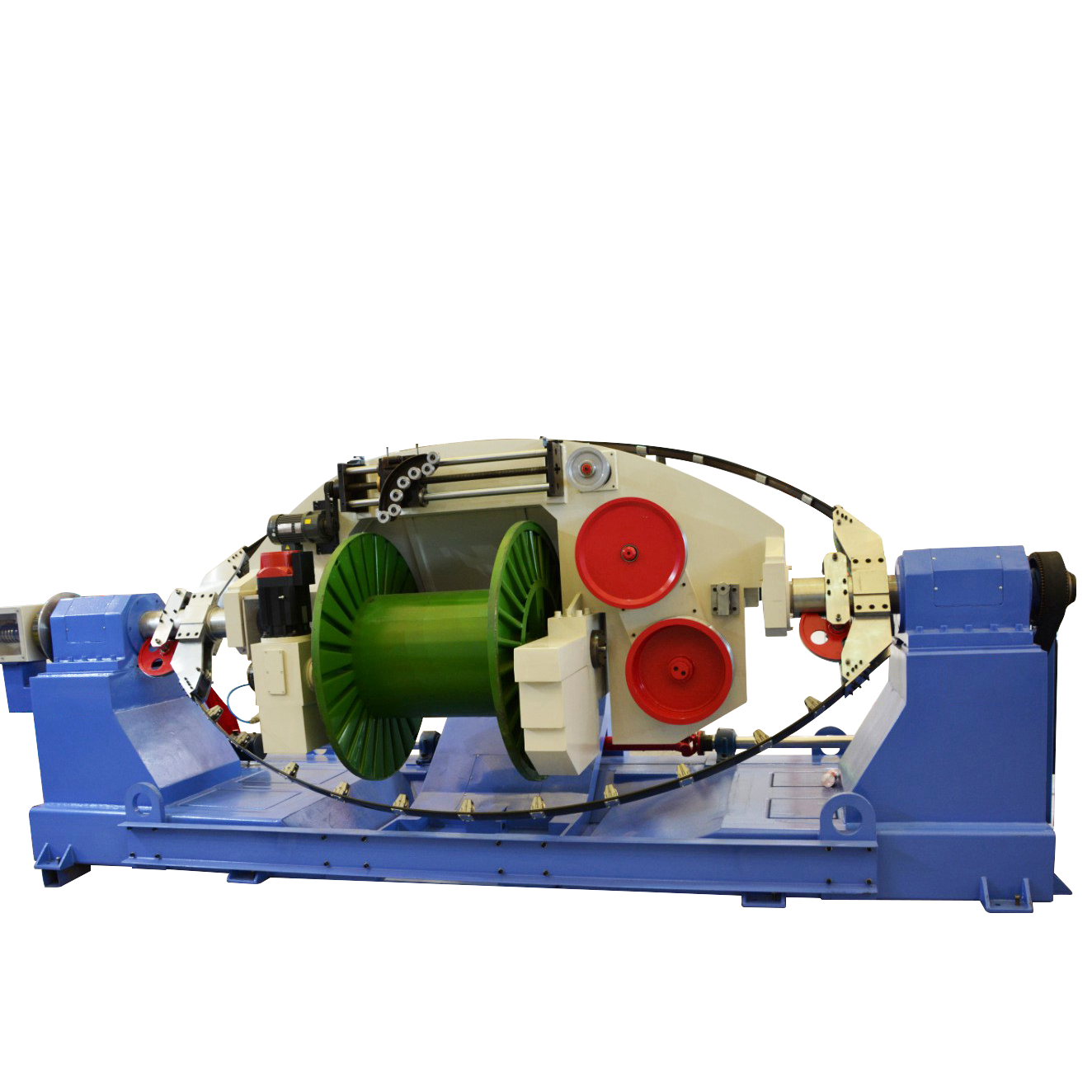

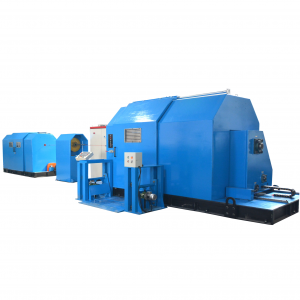

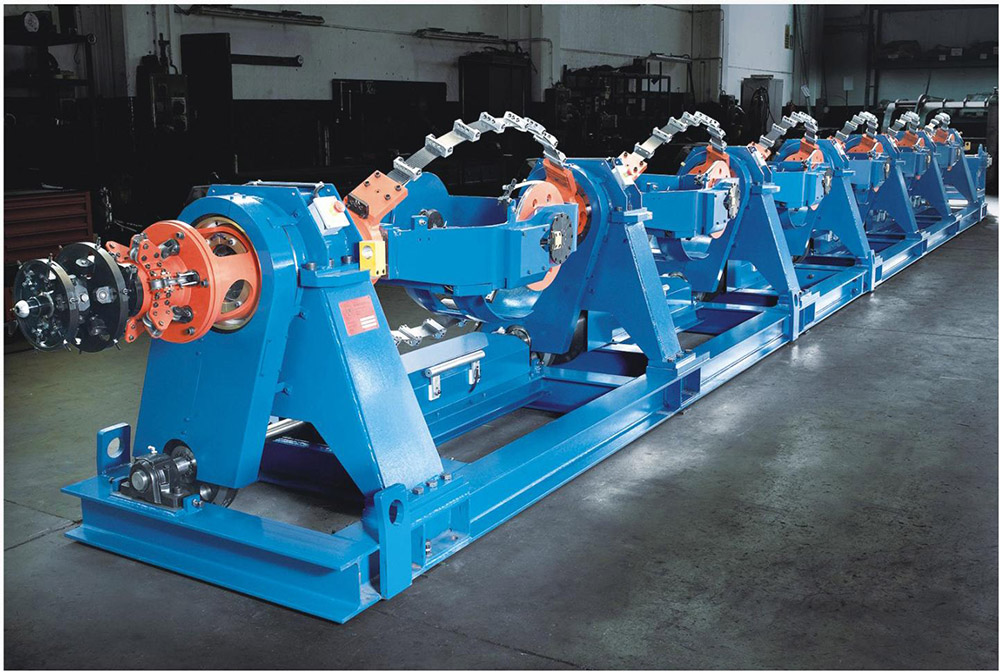

The Bow Type Laying up Machine is equipped with the latest technology to ensure high precision and accuracy in cable manufacturing. It has a computerized control system that allows for easy programming and monitoring of the entire production process. The machine is also equipped with advanced sensors and detectors that ensure consistent quality and performance.

✧ High Performance

The Bow Type Laying up Machine is designed for high-speed cable production, with a maximum speed of up to 800 rpm. It is capable of handling a wide range of cable sizes and types, including power cables, communication cables, and optical fiber cables. The machine is also capable of producing cables with high insulation and shielding properties, ensuring excellent electrical performance.

✧ Multi-Functionality

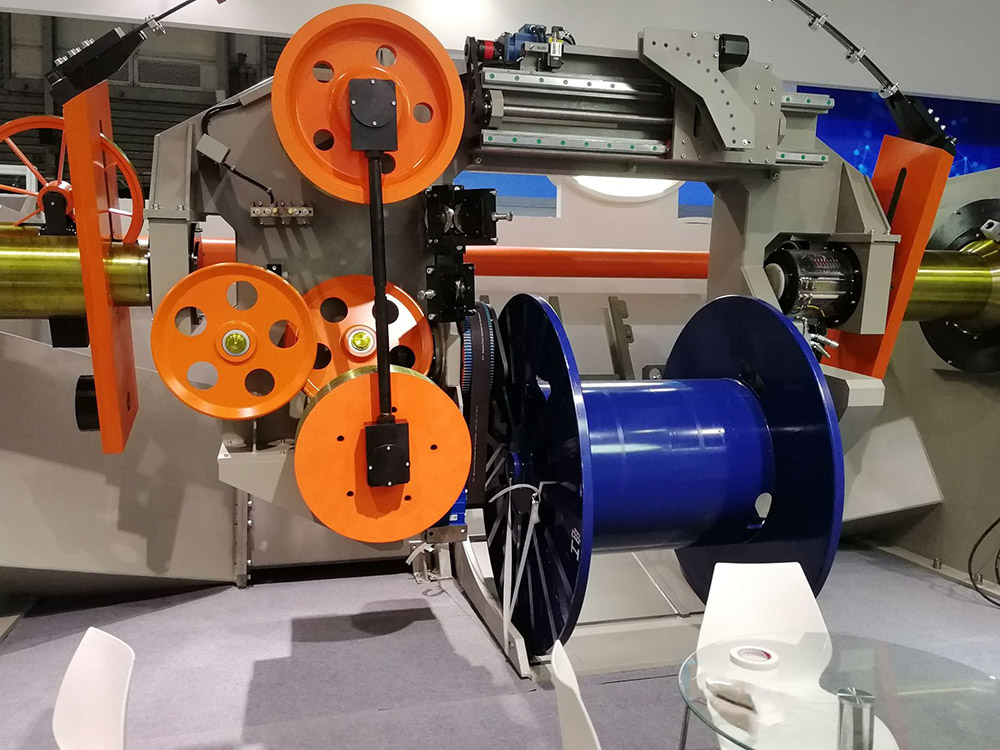

The Bow Type Laying up Machine is a versatile equipment that can perform a wide range of cable manufacturing tasks. It can be used for laying up cables, twisting wires, and stranding conductors. The machine can also be customized to meet specific production requirements, such as adding additional pay-off and take-up units, or integrating a coiling system.

✧ Reliability

The Bow Type Laying up Machine is built to last, with a robust and durable design that ensures long-term reliability and performance. It is made of high-quality materials and components, and is designed to withstand the rigors of continuous operation. The machine is also easy to maintain and repair, with a user-friendly interface that allows for easy troubleshooting and diagnostics.

✧ Conclusion

In conclusion, the Bow Type Laying up Machine is a highly advanced and efficient cable manufacturing equipment that offers a wide range of features and benefits. It is designed to provide high performance, versatility, and reliability to meet the demands of modern cable production. With its advanced technology, high-speed performance, multi-functionality, and long-term reliability, the Bow Type Laying up Machine is the ideal choice for cable manufacturers looking to improve their production processes and increase their competitiveness in the market.

Technical Specifications

| Model |

NHF630 |

NHF1000 |

NHF1250 |

|

| Pay off [mm] |

630 |

1000 |

1250 |

|

| Line speed[M/min] |

120 |

150 |

150 |

|

| Conductor Section [mm²] |

1+3B |

1.5~6 |

4~25 |

10~50 |

|

1+4B |

1.5~6 |

4~25 |

10~50 |

|

|

1+5B |

1.5~6 |

4~25 |

10~50 |

|

| Max.Core [mm] |

6 |

8 |

12 |

|

| Rotor speed [rpm] |

650 |

450 |

350 |

|

| Motor Power[KW] |

1+3B |

35 |

45 |

55 |

|

1+4B |

45 |

55 |

65 |

|

|

1+5B |

55 |

65 |

75 |

|

Characteristics

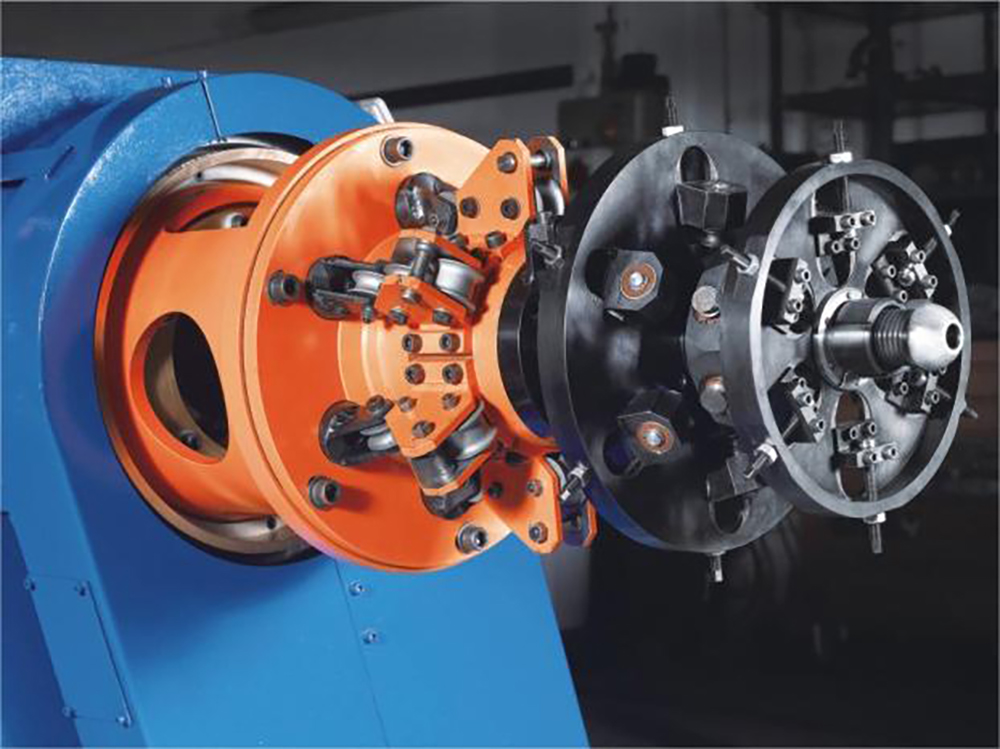

1. Bow type laying up machine working back twist movement to lay up from 2 to 6 cores of aerial cables, control cable or power cable.

2. Main motor, pulling capstan and take up unit are independently driven by AC motor.

3. HMl+PLC control svstem for pre-setting laving up pitch and speed synchronization with the take up unit.

4. Tension control system.Keep the tension constant when going from full bobbin to empty bobbin.

Process

Welding

Polish

Machining

Boring Mill

Assembling

Finished Product

FAQ

A: Yes, we do the following:

-Once the customer informs us that the machine is placed in the correct position, we will send mechanical and electrical engineers to start the machine.

-No-load test: After the machine is completely installed, we first carry out the no-load test.

-Load test: Usually we can produce three different wires for load test.

A: We will conduct dynamic balance test, levelness test, noise test, etc. In the production process.

After the completion of production, we usually carry out no-load operation on each machine before delivery. Welcome customers to visit.

A: We have an international universal color card RAL color card. You just need to tell us the color number. You can customize your machine to match the color matching of your factory.

Answer: Of course, this is our purpose. According to the standards that your cable should follow and your expected productivity, we will design all the equipment, molds, accessories, personnel, inputs and required materials to make documents for you.