- Dongguan NHF Machinery Co., Ltd.

- francesgu1225@hotmail.com

- +8618689452274

✧ Advanced Technology

Single Twist Cabling Machine is equipped with the latest technology that enables it to produce high-quality twisted cables with precision and accuracy. The machine is designed to handle a wide range of cable sizes and types, including copper, aluminum, and fiber optic cables. It features a high-speed twisting system that ensures uniform twisting and reduces cable deformation. The machine also has a sophisticated control system that allows for easy operation and monitoring of the manufacturing process.

✧ High Performance

Single Twist Cabling Machine is designed for high performance and productivity. It can produce up to 500 meters of twisted cable per minute, depending on the cable size and type. The machine is also designed to minimize downtime and maintenance costs. It features a robust construction that ensures durability and long service life. The machine is easy to operate and requires minimal training, which makes it ideal for both small and large-scale cable manufacturing operations.

✧ Multifunctionality

Single Twist Cabling Machine is a versatile equipment that can be used for various cable manufacturing applications. It can produce twisted cables for telecommunications, automotive, and industrial applications. The machine can handle a wide range of cable sizes and types, including single-core, multi-core, and shielded cables. It also features a variety of optional accessories that can be added to enhance its functionality, such as a pay-off system, take-up system, and tension control system.

✧ Reliability

Single Twist Cabling Machine is designed for reliability and consistent performance. It features a robust construction that ensures durability and long service life. The machine is equipped with a variety of safety features that ensure operator safety and prevent accidents. The machine also has a sophisticated control system that monitors the manufacturing process and alerts operators to any issues that may arise. This ensures that the machine operates smoothly and consistently, without any interruptions or downtime.

✧ Conclusion

Single Twist Cabling Machine is a high-performance cable manufacturing equipment that is designed to produce high-quality twisted cables for various applications. It is equipped with advanced technology that ensures precision, accuracy, and reliability. The machine is also versatile and can handle a wide range of cable sizes and types. Whether you need to manufacture cables for telecommunications, automotive, or industrial applications, Single Twist Cabling Machine is the perfect solution for your needs. With its advanced technology, high performance, and multifunctionality, this machine is a must-have for any cable manufacturing operation.

Technical Specifications

|

Model |

NHF630 |

NHF800 |

NHF1000 |

| Wire product of strand |

Communication cable |

||

|

Computer、Instrument cable、Shielding cable |

|||

|

Contyol & Power cable、Fine copper wire standing |

|||

| φ Finish stranded [mm] |

12.Max. |

15.Max. |

20.Max. |

| φ Wire individual[mm] |

1.0~4.0 |

1.0~6.5 |

1.0~5.0 |

| Rotor speed[rpm] |

900 |

700 |

550 |

| Line speed[M/min] |

60.Max |

80.Max |

80.Max |

| Pitch [mm] |

30~300 |

30~300 |

30~400 |

Characteristics

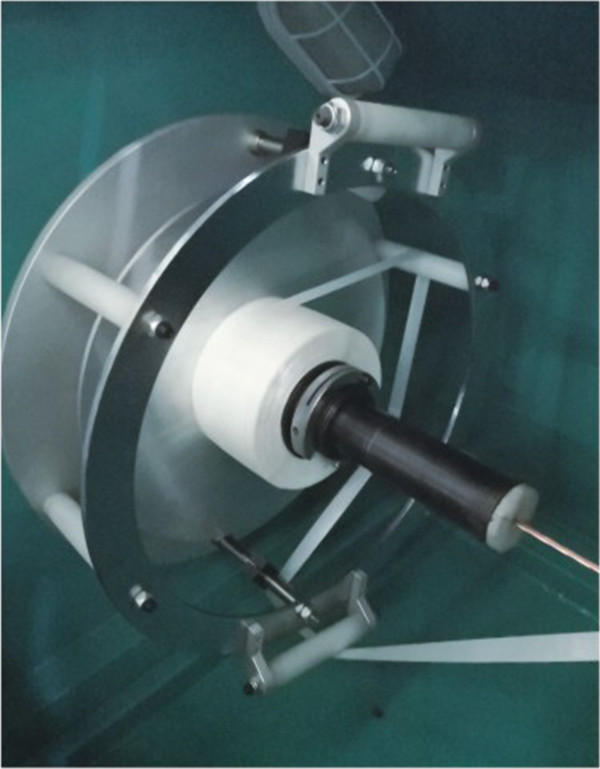

1. Digitally set twist pitch and automatic calculation and correction, no take-up pulley design, direct take-up and take-off function by the take-up shaft

2. The winding shaft is driven by an independent motor, and the wires are arranged by shafts.

3. Center taping machine, power feeder stand, back twist feeder stand.

4. Pitch setting by programmable PLC.Then strand wire wound on spool bobbin without capstans

5. Main motor and spool motor are synchronous controlled by control system,the bobbin loadingarbor traverse stself to wind the wire on reel.

6. Concentric type tapping unit/ motorized pay-off stand/ back-twist pay-off stand.

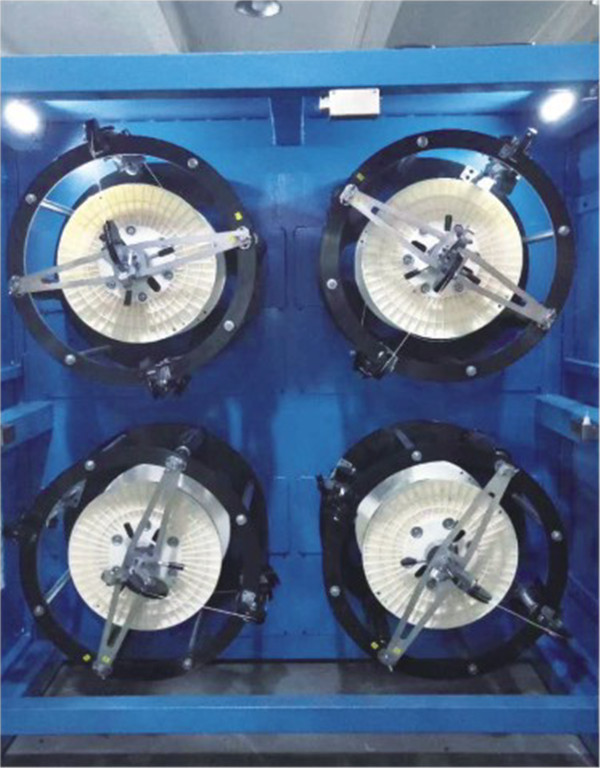

Process

Welding

Polish

Machining

Boring Mill

Assembling

Finished Product

FAQ

A: Yes, we do the following:

-Once the customer informs us that the machine is placed in the correct position, we will send mechanical and electrical engineers to start the machine.

-No-load test: After the machine is completely installed, we first carry out the no-load test.

-Load test: Usually we can produce three different wires for load test.

A: We will conduct dynamic balance test, levelness test, noise test, etc. In the production process.

After the completion of production, we usually carry out no-load operation on each machine before delivery. Welcome customers to visit.

A: We have an international universal color card RAL color card. You just need to tell us the color number. You can customize your machine to match the color matching of your factory.

Answer: Of course, this is our purpose. According to the standards that your cable should follow and your expected productivity, we will design all the equipment, molds, accessories, personnel, inputs and required materials to make documents for you.